Welcome

Your one-stop hub for premium metal fabrication solutions. Share your drawings (including hydraulic/electrical equipment assembly schematics) — we’ll deliver a product tailored to your exact needs.

Production Detail Diagram

01

Laser cutting and tube cutting

Laser Cutting for Sheet Metal:Laser cutting for sheet metal utilizes a high-energy laser beam to instantly melt or vaporize materials, delivering micron-level precision via computer control

Laser Tube Cutting:Laser tube cutting handles round, square & special-shaped metal

02

Bending, rolling, punching

Bending:It can process metal sheets with a thickness ranging from 0.5mm to 20mm, and the angle error is controlled within ±0.5°.

Roll Bending:Our equipment rolls plates 3-100mm thick and up to 3000mm wide. Progressive rolling eliminates stress, ensuring <1.5mm roundness error

Punching:The equipment supports metal sheets with a thickness of 0.1 - 12mm. It can achieve high-speed stamping over 500 times per minute with a hole diameter accuracy of ±0.1mm

03

Welding (robot welding and manual welding)

Intelligent welding robots, coupled with the integration of an automatic feeding machine and a cutting machine, enable highly efficient and stable welding operations. Committed to sustainable production practices, we've implemented a state-of-the-art smoke and dust purification system in compliance with national environmental protection standards.

04

Machining

The company introduced advanced machining equipment integrating cutting-edge tech. These machines can process multiple surfaces in one clamping, improving part accuracy (±0.001mm error) and efficiency while reducing errors from repeated clampings.

05

Acid pickling, phosphating, shot blasting

Acid Pickling:Utilize hydrochloric or sulfuric acid solutions to dissolve rust, oil, and oxide layers, activating the metal surface. Precise control of temperature (50-70°C) and time (5-15 min) prevents over-corrosion, suitable for carbon steel, aluminum alloy, etc

Phosphating:Pickled workpieces are immersed in zinc/iron phosphating solution. A 1-3 g/m² nano-porous film forms via chemical reaction, boosting surface roughness, coating adhesion, and offering basic rust protection

Electrophoretic Coating:Phosphated workpieces act as electrodes in a water-soluble paint tank. Electric fields drive particle deposition, creating 15-30μm films. UF and Anode Cell systems keep the paint stable, ensuring even coating and ≥1000-hour salt spray resistance.

Shot Blasting Process:Shot blasting uses a high-speed impeller (60-120m/s) to propel steel shots and cast steel sands onto workpieces. The impact removes oxide scale, rust, and old coatings, creating a rough surface for better coating adhesion.

06

Paint and powder coating

Utilizes highly integrated smart gear like the KJ264 robot painting workstation and Wagner manual wet spray system to build a human-machine collaborative production line. With rich experience and precise process management, it gains customers' unanimous approval.

07

quality testing

The quality inspection process ensures products meet design standards and industry regulations through full-process, multi-dimensional inspection methods. By integrating visual inspection, non-destructive testing, physical-chemical analysis, and automated inspection equipment, it achieves zero tolerance for defects and quality traceability.

08

assemble

Assembly operation:Assembly must follow process specs. Inspect appearance, dimensions and performance post-assembly to ensure quality and boost efficiency.

09

Packaging and Shipping

For packaging and shipping, balance protection and efficiency. Use standardized packaging, automation, and logistics coordination to standardize operations, reduce cargo damage, and ensure timely delivery.

10

Packaging and Shipping

For packaging and shipping, balance protection and efficiency. Use standardized packaging, automation, and logistics coordination to standardize operations, reduce cargo damage, and ensure timely delivery.

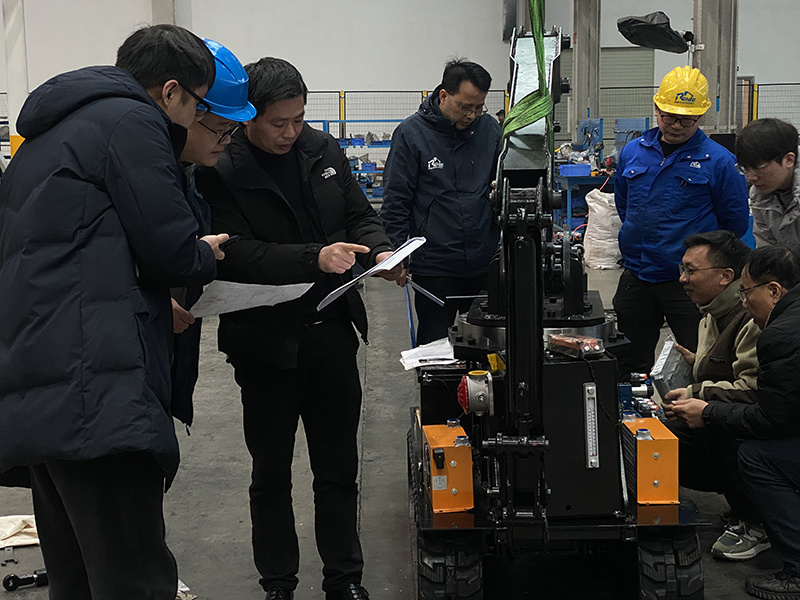

meet our team

Our company attaches great importance to investment in product research and development, aiming to provide higher-quality products for customers around the world. We have a team of highly skilled professionals. The team members have always been committed to the development of auxiliary working attachments, ensuring that the products can be perfectly matched with the original factory excavators while meeting the needs of customers. We also possess rich technical experience in product recognition, export, and international trade services.

our poducts

Our products include excavator attachments, quick couplers, skid steer attachments, mini dumpers, demolition robots, and aerial work platform vehicles. Our products offer the best performance in terms of compatibility, economy, and quality within the industry.

Excavator Attachments

Born from Customer Needs

Mainly used in situations where the work site is narrow, the ground is uneven, and the work content changes frequently, such as infrastructure construction, industrial applications, dock loading and unloading, urban streets, etc.

Mini Dumper

Born from Customer Needs

Mainly used in situations where the work site is narrow, the ground is uneven, and the work content changes frequently, such as infrastructure construction, industrial applications, dock loading and unloading, urban streets, etc.

Quick Couplers

Various tools accessories

Mainly used in situations where the work site is narrow, the ground is uneven, and the work content changes frequently, such as infrastructure construction, industrial applications, dock loading and unloading, urban streets, etc.

Skid Steer Attachment

Born from Customer Needs

Mainly used in situations where the work site is narrow, the ground is uneven, and the work content changes frequently, such as infrastructure construction, industrial applications, dock loading and unloading, urban streets, etc.

Demolition Robot

Born from Customer Needs

Mainly used in situations where the work site is narrow, the ground is uneven, and the work content changes frequently, such as infrastructure construction, industrial applications, dock loading and unloading, urban streets, etc.

Aerial Work Platform Vehicles

Born from Customer Needs

Mainly used in situations where the work site is narrow, the ground is uneven, and the work content changes frequently, such as infrastructure construction, industrial applications, dock loading and unloading, urban streets, etc.

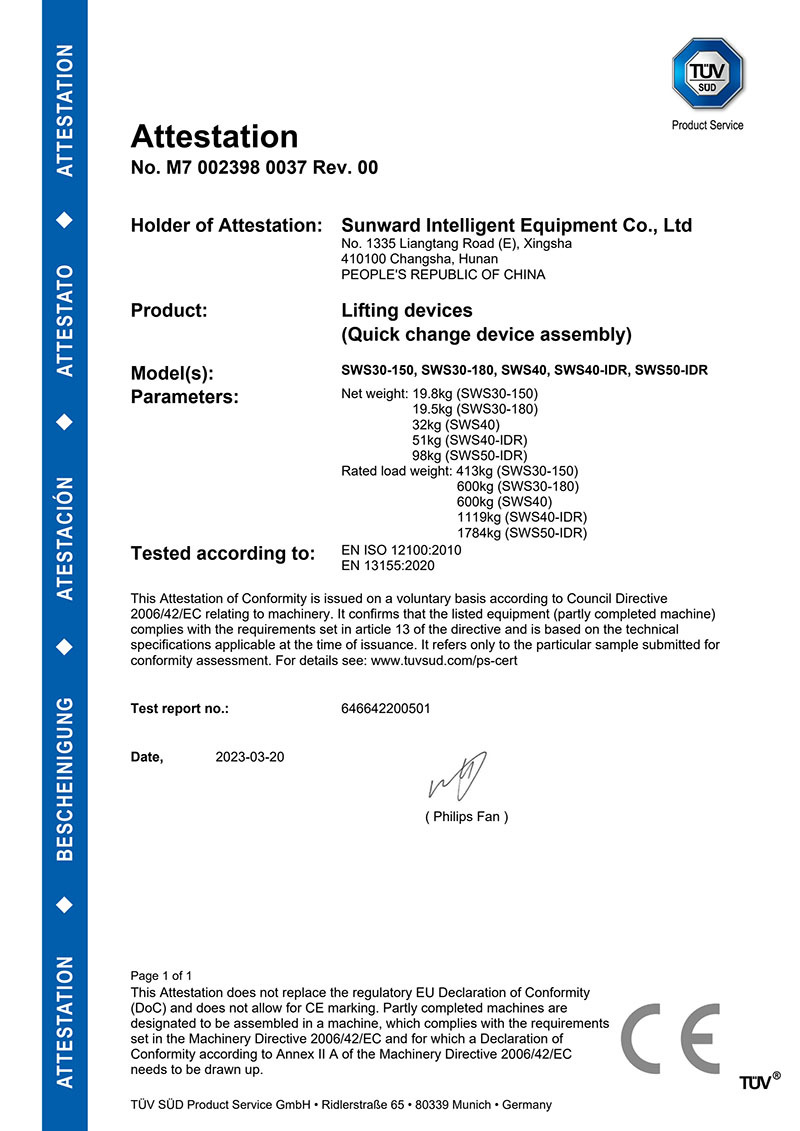

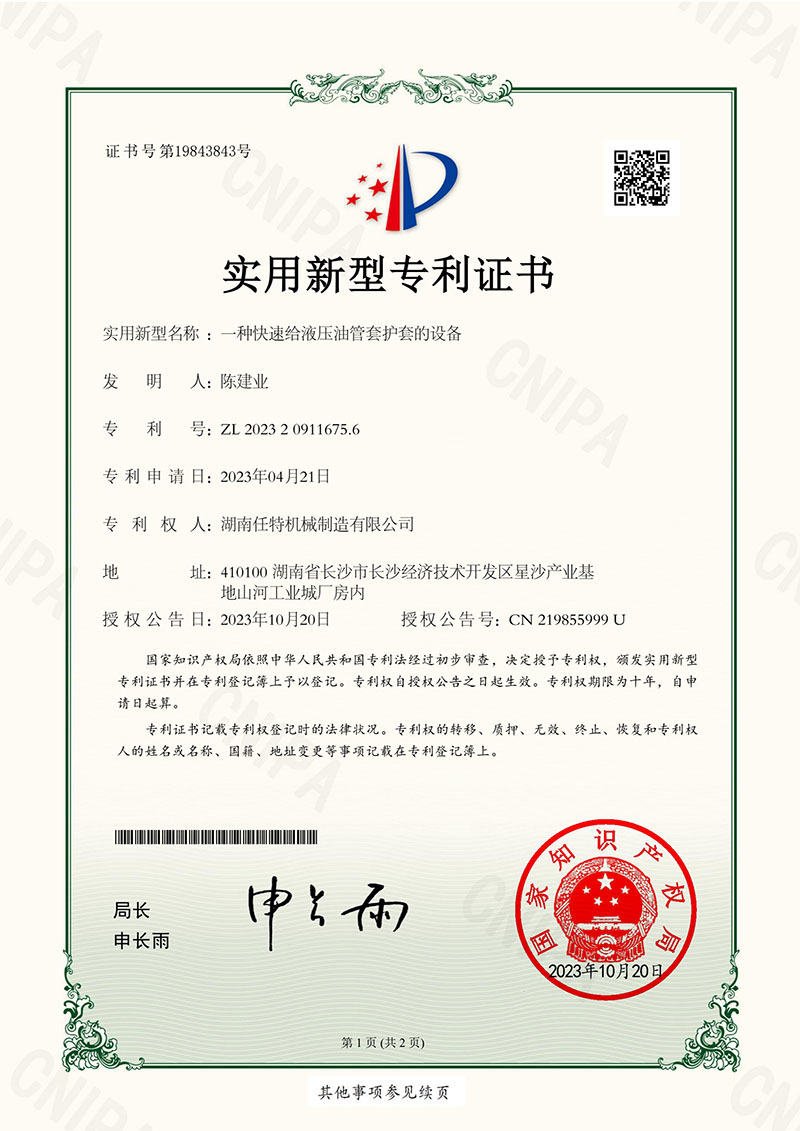

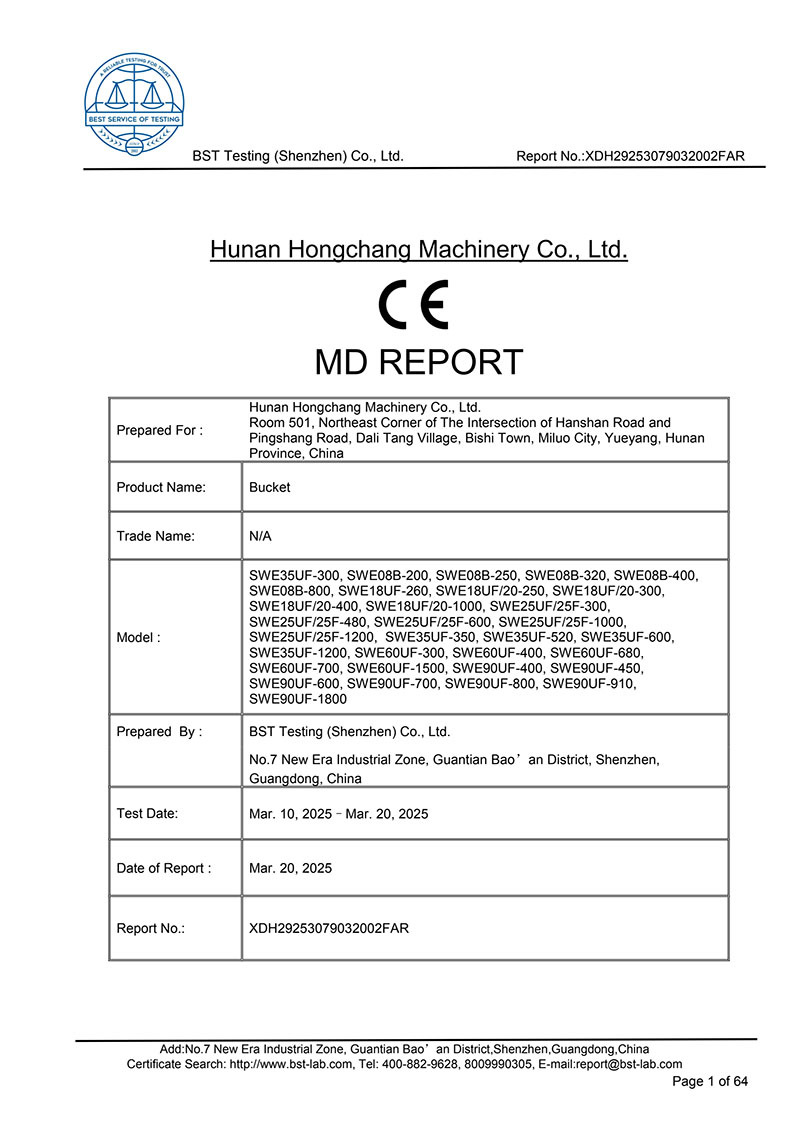

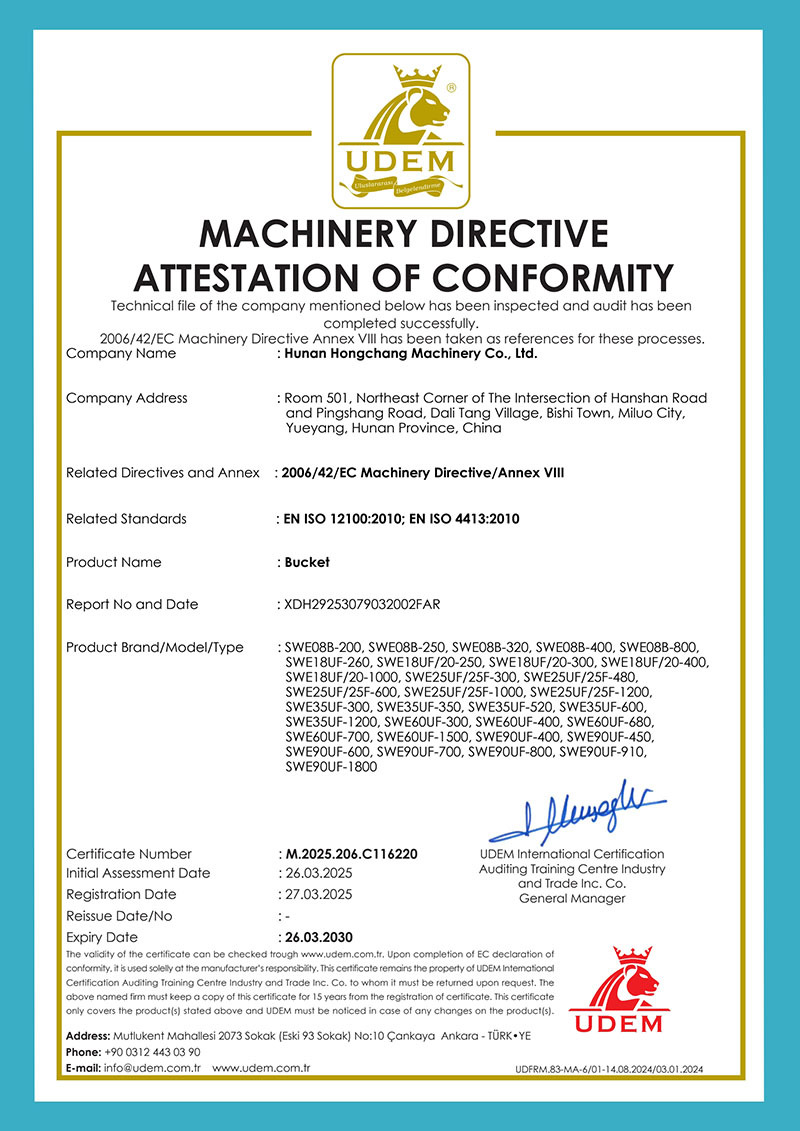

our certifications

The Elegance of the Team

It is a team full of passion and professionalism. With our profound industry accumulation, keen market insight, and accurate grasp of customers' needs, we have stood out in the fierce foreign trade market, creating customized solutions for each customer and driving the vigorous development of our business.

why choose us

Guided by the principle “Born from Customer Needs” and an unwavering commitment to quality, Hongchang leverages decades of industry expertise to build core competitive advantages. The company is dedicated to becoming a world-class leader in engineering equipment attachments, delivering excellence across domestic and international markets.

high Quality

We select high-quality materials to ensure that our products can withstand harsh working conditions.

customization

We offer customization options and customize the products according to specific application requirements to ensure optimal performance and efficiency.

excellent Support

We provide excellent customer service and support, ensuring comprehensive coverage from the initial consultation all the way to installation and maintenance.